Have you ever seen tiles popping up, cracking, or sounding hollow just months after installation? If yes, you already know the frustration. And if you’re planning a new project, whether it’s a home, commercial space, or industrial flooring, this is something you definitely want to avoid.

At Famsa Polymers, we’ve worked closely with contractors, architects, and builders across Pakistan. One thing we’ve learned over the years is this: tile adhesive bond strength is not a “technical extra,” it’s the foundation of long-lasting tile work.

When the bond is strong, tiles stay firmly in place for years. When it’s weak, repairs become expensive, time-consuming, and stressful. That’s why today, we’re answering a very common and important question: How can I test the bonding strength of tile adhesive?

Let’s break it down in a simple, practical, and easy-to-understand way how to test the bonding strength of tile adhesive, why it matters, and how to make sure your tiles stay put for the long haul.

What Is Bonding Strength in Tile Adhesives?

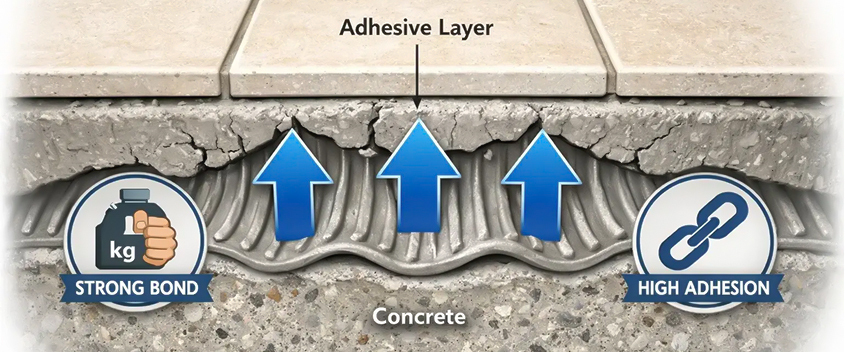

Think of tile adhesive like the handshake between your floor and your tiles. A firm, reliable handshake means trust, stability, and long-term performance. Bonding strength measures exactly how well your tile adhesive sticks your tiles to surfaces like concrete, wood, or even existing tiles.

When the bonding strength is strong:

- Tiles resist lifting, cracking, or shifting.

- Floors remain safe under daily wear and tear.

- Your investment in tiles, epoxy flooring, or epoxy resin applications lasts longer.

When bonding strength is weak, even the most aesthetically pleasing tiles can fail quickly. That’s why choosing a trusted tile adhesive manufacturer in Pakistan is crucial. We focus on creating adhesives that don’t just stick, they bond with precision and reliability.

Types of Tile Adhesive Bonding Strength Tests

Now, let’s get practical. Testing bonding strength isn’t just for labs; it’s something you can understand and even check on-site if needed. Broadly, there are two main categories of tests:

- Lab-Based Testing – Highly precise, using machines to measure pull, shear, or compressive strength.

- On-Site Practical Checks – Quick, real-world checks to see how well the adhesive is performing in actual conditions.

Both methods have their place, depending on whether you’re a professional contractor or a DIY enthusiast. Let’s dive.

Lab-Based Testing: The Scientific Way

If you’re curious about the exact numbers behind your tile bond, lab testing is the gold standard. Labs can measure bonding strength with scientific precision using a few common methods:

- Pull-Off Test: This method measures how much force it takes to pull a tile straight off the surface. Think of it as testing whether your handshake can hold under pressure.

- Shear Strength Test: This test applies a horizontal force to check how well your tiles resist sliding or shifting. Very important for large floor areas or walls.

- Compressive Strength Test: This checks whether the adhesive can handle heavy weights pressing down. Crucial for areas with heavy furniture or machinery.

When manufacturers perform these tests, you get assurance that your tile adhesive is designed to meet high-performance standards. And yes, this includes specialty applications like epoxy flooring or epoxy resin installations where durability is everything.

On-Site Practical Checks: Quick and Effective

Not everyone has access to a lab, and that’s perfectly fine. You can still do simple tests to ensure your tile bond is strong before committing to full installation. Here’s how:

- Tap the tile lightly with a rubber mallet; a hollow sound can indicate poor bonding.

- Try gently pressing on the edges of the tile to see if there’s any movement.

- Observe early signs after installation, like lifting corners or visible gaps.

These checks may seem basic, but they’re surprisingly effective. They give you a first-hand feel of the adhesive’s performance. And if you spot anything, it’s easier to correct early, saving time, money, and frustration.

Common Mistakes That Reduce Tile Adhesive Bonding Strength

Even the best tile adhesive manufacturer in Pakistan can’t compensate for some common errors. Here’s where things often go wrong:

- Incorrect Surface Preparation: Dust, oil, or uneven surfaces can reduce adhesion dramatically.

- Wrong Mixing Ratio: Using too much water or powder affects bonding strength.

- Skipping Curing Time: Tiles need time to bond properly; rushing this step compromises durability.

- Using the Wrong Adhesive: Not every adhesive works for every surface or tile type epoxy resin, ceramic, or stone tiles all have different requirements.

Avoiding these mistakes ensures that your tile adhesive works exactly as it’s supposed to, delivering a strong, long-lasting bond.

How Famsa Polymers Ensures Superior Tile Adhesive Bond Strength

You might be wondering: “Bond strength sounds important, but how do I know my tiles will actually stay in place?” That’s exactly the question we hear from builders, homeowners, and contractors across Pakistan.

At Famsa Polymers, strong bonding isn’t left to chance. So how do we ensure every batch of our tile adhesive performs flawlessly?

“Do lab tests really matter?” Absolutely. Every product undergoes rigorous testing to check pressure resistance, shear strength, and long-term durability. Whether it’s ceramic, porcelain, or specialty epoxy flooring and epoxy resin, your tile bond stays strong.

“Isn’t all adhesive the same?” Not at all. Our formulations use a precise mix of polymers, resins, and additives to create a consistent, reliable bond that lasts.

“What if my surface isn’t standard concrete?” No problem. From cement screeds to existing tiles, even challenging surfaces like epoxy resin, our adhesives are tailored to grip perfectly.

And finally, “Does this work outside a lab?” Definitely. We collaborate with contractors and architects across Pakistan, refining our products based on real-world feedback so lab-tested performance meets site-ready reliability.

Choosing Famsa Polymers isn’t just choosing a tile adhesive manufacturer in Pakistan, it’s choosing peace of mind. Confidence that your tiles stay put, your investment is secure, and your floors remain flawless for years.

Choosing the Right Tile Adhesive for Maximum Bonding Strength

Choosing the right adhesive isn’t complicated, but it does matter. Here’s what to consider:

- Surface Type: Different surfaces require different bonding solutions.

- Tile Material: Ceramic, porcelain, or stone tiles all have unique needs.

- Load and Environment: Floors in high-traffic areas or wet spaces need stronger adhesives.

We recommend consulting with a trusted tile bond manufacturer in Pakistan like Famsa Polymers to match your project with the perfect adhesive. The right choice ensures maximum bonding strength, fewer repairs, and long-lasting results.

Strong Bonding Starts with the Right Testing

At the end of the day, testing the bonding strength of your tile adhesive isn’t just about numbers or machines; it’s about confidence. Confidence that your floors will stay solid, your walls will stay beautiful, and your tiles will stay exactly where you want them.

Whether you rely on lab-based tests, simple on-site checks, or trust a high-quality tile adhesive manufacturer in Pakistan like Famsa Polymers, one thing is clear: strong bonding starts with the right approach and the right product.

So, the next time you wonder, “How can I test the bonding strength of tile adhesive?” remember it’s a mix of smart testing, careful preparation, and choosing adhesives designed for performance. With Famsa Polymers, you’re not just tiling a surface; you’re creating a floor that lasts, a bond that endures, and a project you can proudly stand on.